Power supply: AC380V, 50Hz;

Dimensions: LxBxH=4142x2261x4100mm

Motor power: 2.2Kw

Lifting weight: (including dough tanker) 1500Kg

Lifting time: 37 seconds / rising once

Performance Characteristics of Dough Lifter

The dough lifter is a special equipment in the production process of bread crumbs. It mainly lifts the dough after the second proofing to the height required by the

dough divider for the next process operation of the dough.

1.The equipment is easy to operate and has high operating efficiency;

2. Easy to maintain and adjust;

3. It is fast to enter and exit the dough tanker;

4. In addition to the transmission system, it is made of 304 stainless steel, which is safe and hygienic and easy to clean.

Main Technical Parameters

Power supply | AC380V, 50Hz |

Dimension | LxBxH=4142x2261x4100mm |

Motor power | 2.2KW |

Lifting weight | (Including dough tanker) 1500Kg |

Lifting time | 37 seconds / rising once |

Installation and Debugging

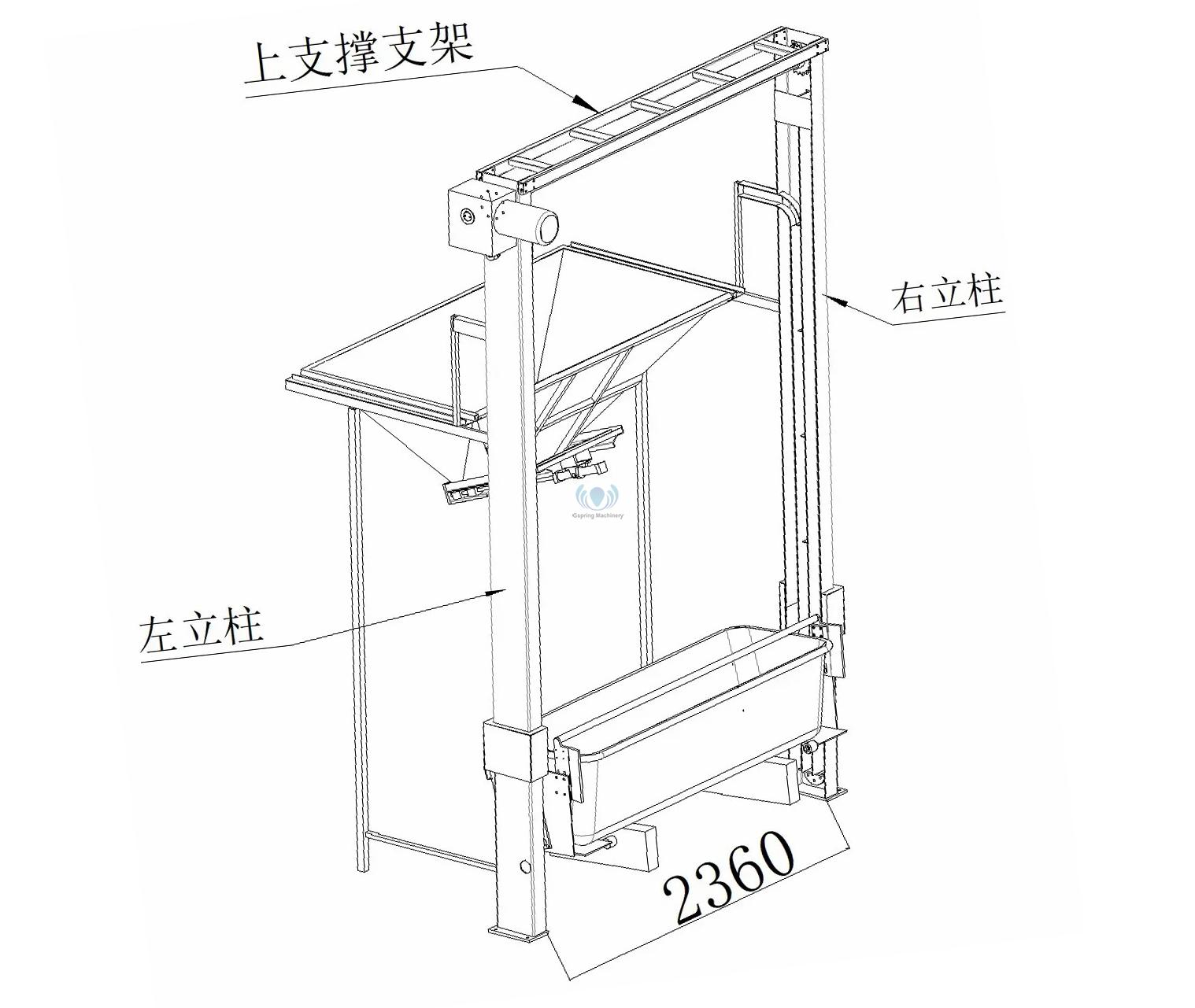

1. Install the rack

(1) Install the sprocket on the main shaft, on the side with the keyway, make the sprocket lean on the step, and the other end of the sprocket, measure the distance

between the end face of the inner gear tooth of 2490mm;

(2) Put the left and right uprights on the main shaft;

(3) Install the square bearing on the main shaft, connect it with the left and right uprights with bolts, pay attention to the inward direction of the bolt head;

(4) Install the support bracket, measure the distance from the sprocket to the outside of the left and right columns, and make them equal;

(5) Install the reducer so that the small end of the torque arm is inserted into its fixed seat, tighten it, and install a baffle plate on the outer end face of the main shaft;

(6) Stand up the installed parts, install them in place, measure the size of 2360mm, and fix them with anchor screws.

2. Install hopper and basket

(7) Check the movement of each functional component of the hopper, and there is no abnormality;

(8) Adjust the chain so that the upper and lower positions of the basket mounting plate correspond, adjust the chain tightness through the adjustment holes on the outside

of the left and right uprights (at the round protective cover), and fasten the bolts;

(9) Install the basket on the chain of the main body, adjust the adjusting screw to make the roller move vertically up and down, and fasten the screw;

(10) Adjust the position of the hopper so that the gap between it and the basket or dough tanker is 20±10mm, and ensure the same spacing, and fix the hopper;

(11) Push the dough tanker into the basket, adjust the basket lever, so that the tanker can be pushed in and pulled out normally, the recommended clearance is 35-40mm;

(12) Apply an appropriate amount of butter to the pre-friction surface of the chain and the basket during the up and down operation, the operation is normal, and the dough

tanker can turn freely;

(13) After running for a period of time, adjust the chain tension through the adjustment holes on the outside of the left and right uprights (at the round protective cover);

3. Installation platform

(14) Install the short platforms on both sides and hold them up with Y-shaped columns;

(15) Install the long platform and fasten it with the short platform with bolts;

(16) Install the vertical ladder, fasten it with bolts and the short platform, and fix the ground with anchor screws.

Equipment Operation

1. After the installation of the equipment is completed, the site should be cleaned up;

2. Check the wiring condition of the power supply and check that the power supply voltage meets the requirements;

3. Run empty, no abnormality, and then run with load;

4. When the load is running, adjust the position of the travel switch to meet the requirements of the current work.

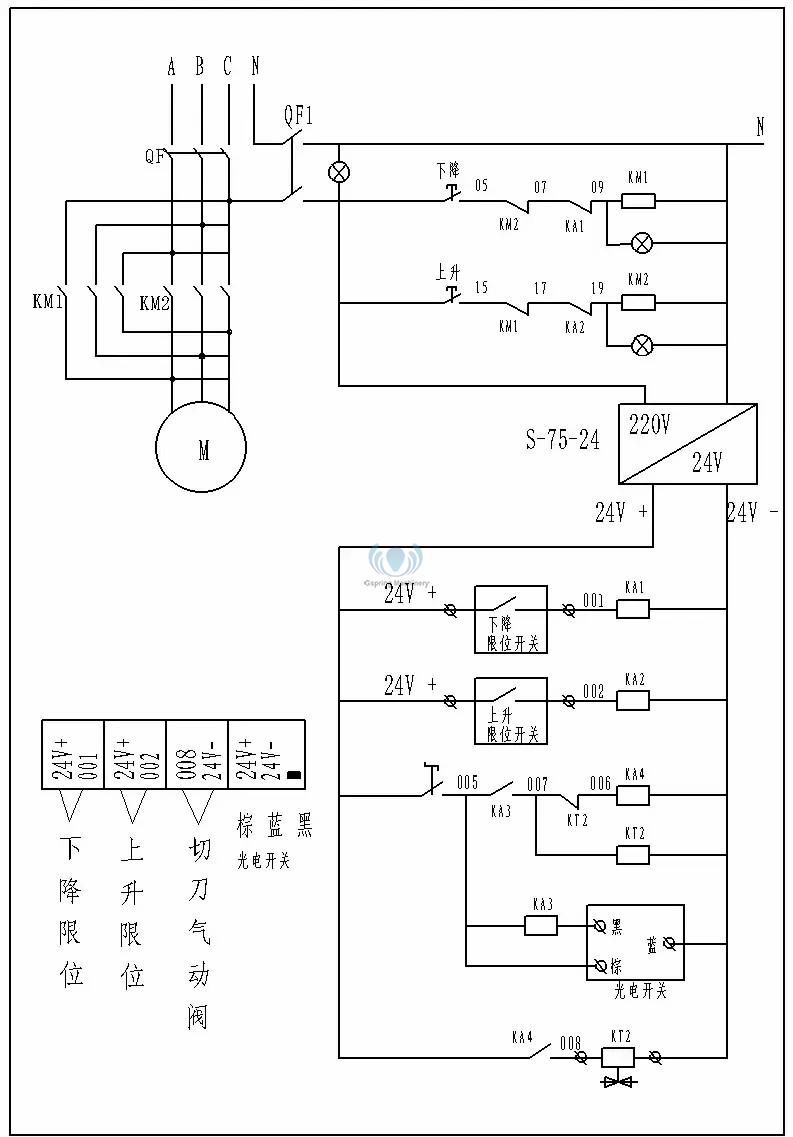

Electrical Operation Diagram

You May Ask Further

We are the professional supplier for High Quality Fermented /Panko Bread Crumbs Production Line, if any questions about the machine, pls email grace@chinagspring.com.

Contact: Grace Guo

Phone: +8617686617441

E-mail: grace@chinagspring.com

Whatsapp:+8617686617441

Add: No. 68, Jiuquzhuang Road, Shizhong District, Jinan, Shandong, China, 250000

We chat