Microwave technology is the best solution for evaporate water & sterilize, microwave drying process consist of three main components: generator, waveguide, and applicator. The applicator uses the microwave energy to dry the material from all directions, not like hot air heating, from outside to inside, but with water molecules oscillating at the frequency of the generator.

Our machine choose 2450MHZ microwave working frequency, which can be suitable for kinds of different industrials application, Gspring microwave technology can customize different industrial microwave machine.

1. Working Environment, Gspring can supply microwave vacuum dryer and normal Industrial Microwave Dryer;

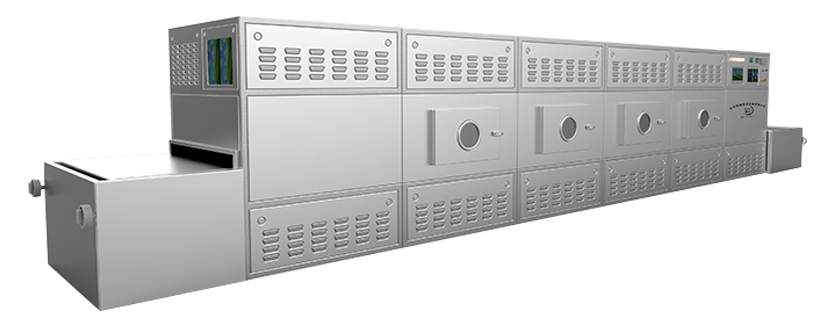

2. Automatic Difference; Gspring can supply batch type microwave machine and continuous microwave machine, batch type microwave machine is mainly used for lab scale or small capacity. based on different layer, it can divided into one layer tunnel dryer or multi-layer tunnel dryer;

3. Cooling Difference; Gspring can supply air cool microwave machine, and water cool microwave machine; Air cooler is more efficient, suitable for small capacity food industry, water-cooler can run 24 *7,especially for large scale non-food industry, such as chemical industry, coal industry, paper & wood industry etc.

4. Application Difference: we can supply microwave machine in different application, such as Food industry, Medical Industry, Chemical Industry, Paper/Wood/Ceramics Industry, Coal/Construction Material

Contact: Grace Guo

Phone: +8617686617441

E-mail: grace@chinagspring.com

Whatsapp:+8617686617441

Add: No. 68, Jiuquzhuang Road, Shizhong District, Jinan, Shandong, China, 250000

We chat