The Principle of Microwave Drying

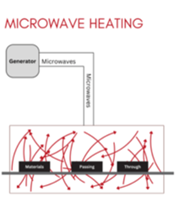

Microwave heating is a process that uses microwave energy to heat and dry materials. Microwave is one electromagnetic waves with a wavelength range of approximately 1 mm to 1 m and a frequency range of 300 megahertz (MHz) to 300 gigahertz (GHz). The most commonly used microwave frequency in industry 2450MHZ. There is a picture which show microwave generator heating directions as follows.

1. Molecular Polarization: When microwaves pass through different materials, water molecules and other polar molecules in the materials will be polarized due to the rapid change of the microwave electric field, so friction and heat will be generated.

2. Internal Heating: Microwave heating is unlike traditional external heating(thermal-transfer), microwaves can directly heat the molecules inside the material. So it’s more uniform and faster to reach heating result.

3. Heat Conduction: When the molecules inside the material generate heat due to microwaves, the heat can be transferred to the surface and deeper areas of the material by heat conduction to accelerate whole material heating.

4. Water Evaporation: Microwave heating can accelerate water evaporation. When the water in the material is heated, the movement speed of water molecules is accelerated, and it is easier to evaporate from the surface of the material, thereby achieving drying.

5. Non-thermal Effects: Microwaves may produce some non-thermal effects, such as the influence of electromagnetic fields on biomolecules, which can be used for sterilization and extending shelf life in food processing.

Microwave Drying Advantages

1. Heating Speed Faster: Microwave heating is a kind of internal heating. The heated material itself can become a heating element. Both factors work together to heat the material in a very short time.

2. Energy-saving & Efficient: Microwaves are generated by water molecules in the material absorbing microwaves and generating heat, the thermal efficiency can reach about 90%. Except for transmission loss, there is no other loss, so it is energy-saving and efficient.

3. Uniform Heating: Materials can absorb microwaves and generate heat inside and outside at the same time. So it can achieve internal and external heating regardless of the shape

4. Easy Control & Maintain:Microwave heating only requires basic conditions of water and electricity. As long as the microwave power is controlled, the heating process can be controlled. Auxiliary monitoring and other detection methods can achieve automatic industrial process.

5. Environmental Process:Microwave drying won’t generate high environmental temperatures, smoke and noise. But also no waste water, waste gas, waste materials etc. So it truly achieves environmentally drying.

You May Know Further:

1. What's the latest technology in Industrial Microwave Dryer?

2. How many types microwave ovens in the market?

3. How to choose a suitable Industrial Microwave Dryer?

Gspring machinery from China is the professional manufacturer of industrial microwave machinery. We have more than 15 years experience on export, export to all over the world, like USA, Canada, Russia, India, Sri Lanka, Turkey, Vietnam, Indonesia, Pakistan, Philippines, Brazil, Egypt, Czech, Singapore, Armenia, Iraq, Iran, Malaysia, Bangladesh, Mexico, Peru, Algeria, Poland, Thailand, Nepal, Azerbaijan etc. we can customized machinery specially based on your specific request. Welcome to contact grace@chinagspring.com to learn more.

Contact: Grace Guo

Phone: +8617686617441

E-mail: grace@chinagspring.com

Whatsapp:+8617686617441

Add: No. 68, Jiuquzhuang Road, Shizhong District, Jinan, Shandong, China, 250000

We chat