1、The forming,heat sealing,batch marking,indentation,blanking and other devices are all positioned by a rackmade mandrel. When the handle is shaken,all devices can move easily and freely on the mandrel.The machine is equipped with a ruler, which is convenient for calibration and rapid and accurate positioning.

2、The servo motor is used to pull the film,which effectively improves the stabity of the product and increases the adjustable range of the traction stroke

3、The packaging thickness of special materials is ≥14mm.It adopts positive pressure air molding and is equipped with a mechanical punch to ensure that the blister molding is uniform and straight.It is applicable to the packaging of large dense plls, nedical devices and other large size or special shapes.

4、The main transmission part adopts the parallel shaft helical gear reducer,and the molding,heat sealing,indentation and other molds adopt the pin positioning,the pressing plate is fixed,the positioning is accurate,the mold change is convenient,and the packaging materials are saved

5、The electrical control system adopts imported brands:the PCL touch screen temperature control module adopts Siemens brand,the servo motor adopts Panasonic brand,and the encoder adopts Omron.

Features

1、The forming,heat sealing,batch marking,indentation,blanking and other devices are all positioned by a rackmade mandrel. When the handle is shaken,all devices

can move easily and freely on the mandrel.The machine is equipped with a ruler, which is convenient for calibration and rapid and accurate positioning.

2、The servo motor is used to pull the film,which effectively improves the stabity of the product and increases the adjustable range of the traction stroke

3、The packaging thickness of special materials is ≥14mm.It adopts positive pressure air molding and is equipped with a mechanical punch to ensure that the blister

molding is uniform and straight.It is applicable to the packaging of large dense plls, nedical devices and other large size or special shapes.

4、The main transmission part adopts the parallel shaft helical gear reducer,and the molding,heat sealing,indentation and other molds adopt the pin positioning,the

pressing plate is fixed,the positioning is accurate,the mold change is convenient,and the packaging materials are saved

5、The electrical control system adopts imported brands:the PCL touch screen temperature control module adopts Siemens brand,the servo motor adopts Panasonic

brand,and the encoder adopts Omron.

Note

1、Optional Equipped with Photocell detecting device

2、Optional Equipped with Acylic glass cover

3、Optional Equipped with ink jet coding device

4、Optional special feeder

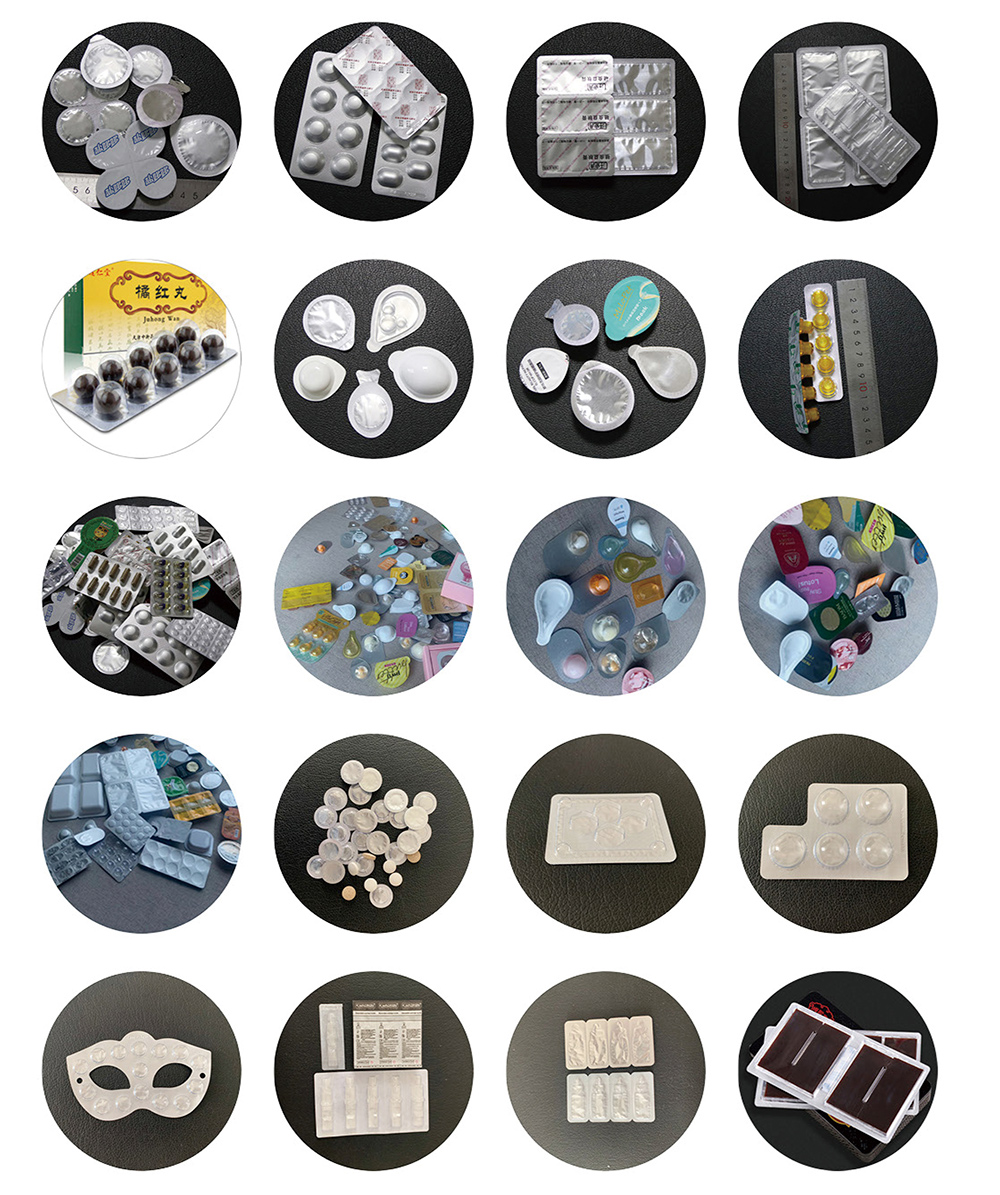

Sample of aluminum plastic blister packaging machine

Technical Parameters

Model 型号 | DPP-260 | DPP-320 |

Cutting frequency(次/分)冲裁次数 | 10-40 | 10-40 |

Production capacity生产能力(版/时) | 2400-9600(标准尺寸80x57,一出四版) | 2400-12000(标准尺寸80x57,一出五版) |

Standard travelrange标准行程范围 (mm) | 40-140(标准) | 40-180(标准) |

Max fomming area and depth(mm) 最大成型面积及深度 | 240X140 标准深度≤ 14mm)最大深度26mm | 360X160 标准深度≤14mm)最大深度35mm |

Power and total power电源及总功率 | 三相四线 380V/220V 50HZ 8.5KW | 三相四线 380V/220V 50HZ 9.5KW |

Motor Power(kw)电机功率 | 2.2 | 2.2 |

Air pressure(MPa)空气压力 | 0.6-0.8 | 0.6-0.8 |

PVC sheet(mm )PVC 硬片 | 0.25(0.15-0.5)x260

| (0.15-0.5)x320 |

PTP aluminum foil PTP铝箔(mm) | 0.02-0.035x260 | 0.02-0.035x320 |

Dialysis paper透析纸 (mm) | 50-100gx260 | 50-100gx320 |

Overall dimensions整机外形尺寸(mm) | 3310x710x1700(可分体,尺寸:左长1950;右长1360) | 4350x770x1750 |

Total Weight 整机重量 (kg) | 1400 | 1800 |

Contact: Grace Guo

Phone: +8617686617441

E-mail: grace@chinagspring.com

Whatsapp:+8617686617441

Add: No. 68, Jiuquzhuang Road, Shizhong District, Jinan, Shandong, China, 250000

We chat